Business Scenario:

In SAP PS (Project System), the subproject concept is used to divide a larger project into smaller, more manageable parts. A subproject is essentially a mini-project that is part of a larger project and has its own set of deliverables, budget, and timeline. In this blog, we will explore the concept of subprojects in SAP PS and how they can be used to improve project management.

Subproject Concept in SAP PS

The subproject concept in SAP PS involves breaking down a larger project into smaller, more manageable parts. Each subproject is managed as an individual project, with its own WBS (Work Breakdown Structure) and project team. A subproject can be used to manage specific deliverables within the larger project or to manage a portion of the project that requires specialized expertise or resources.

The subproject concept in SAP PS is closely related to the concept of the project hierarchy. The project hierarchy in SAP PS is a way of organizing projects and subprojects into a tree-like structure, with the main project at the top and the subprojects below it. This hierarchy can be used to provide a clear overview of the entire project and the relationships between the different subprojects.

Benefits of Subprojects in SAP PS

There are several benefits to using subprojects in SAP PS. These include:

Improved Project Management: By breaking down a larger project into smaller subprojects, project managers can better manage the project and ensure that each deliverable is completed on time and within budget.

Clearer Communication: The subproject concept in SAP PS provides a clear way to communicate project goals and expectations to team members, stakeholders, and sponsors. It also provides a clear structure for reporting on project progress.

Resource Optimization: Subprojects in SAP PS allow project managers to allocate resources more effectively. They can assign resources to specific subprojects based on their skills and expertise, which can lead to better project outcomes.

Greater Flexibility: The subproject concept in SAP PS allows project managers to make changes to the project plan more easily. If a specific subproject is not going according to plan, it can be adjusted without affecting the rest of the project.

Practical use:

Subprojects are an essential tool in SAP PS (Project System) for breaking down larger projects into smaller, more manageable parts. They allow project managers to better manage specific deliverables within a larger project or manage portions of the project that require specialized expertise or resources. In this blog, we will explore the subproject concept in SAP PS, its benefits, and its applications in project management.

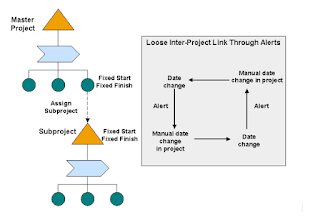

When you work with subprojects, a task of a project is created as a separate subproject, for example, because a different department or a subcontractor is responsible for the task. To map this relationship, you create an inter-project link between the task of the master project and the project definition of the subproject.

A task of a master project can only ever be linked to a single subproject. The subproject can, however, also be the master project for other subprojects which enables you to map multilevel project hierarchies.

The following graphic explains the scenario:

1. Subproject Field as Label

The subproject field works as a labeling mechanism that enables you to organize and manage WBS (Work Breakdown Structure) elements hierarchically. Each subproject is identified by a description that is defined in the WBS element. When you subdivide the WBS element at a later point in time, the subproject's assignment is copied to the new lower-level WBS elements. This ensures that the subproject's scope is retained across the WBS hierarchy.

2. Transferring Prize Agreements between WBS Elements

Subprojects can be used to transfer prize agreements between WBS elements. To achieve this, you divide the work breakdown structure into subprojects. A subproject is made up of WBS elements hierarchically connected. After creating the subproject and assigning it to the WBS element, the system will give you the option to select the subproject in budgeting. This allows you to control the budget area-wise, making it easier to monitor resource utilization and track expenses.

3. Budget Control using Subprojects

If the company is using intracompany billing or transfer pricing between departments, subprojects are a helpful tool for controlling the budget. In this scenario, you can create Level 2 WBSE for each department and create other breakups for each department under it. In dynamic selection of project report, you can mention the project type so that you can get the report for a department. Using subprojects in this way enables you to allocate resources more effectively and optimize the use of available funds.

4. Application in Project Management

Subprojects in SAP PS are a powerful tool for managing complex projects. By dividing a project into smaller subprojects, project managers can improve project management, optimize resources, and provide clear communication and reporting on project progress. Each subproject is managed as an individual project, with its own WBS and project team. The subproject concept in SAP PS allows project managers to make changes to the project plan more easily. If a specific subproject is not going according to plan, it can be adjusted without affecting the rest of the project.

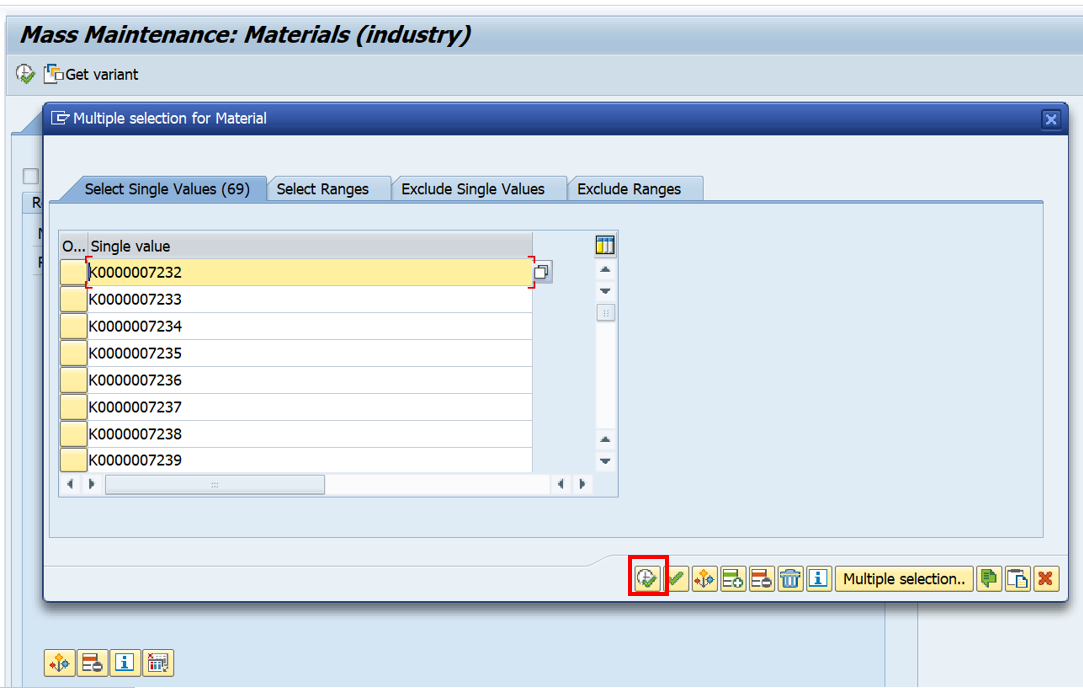

Configuration T code- OPUM

Conclusion

In conclusion, the subproject concept in SAP PS is a powerful tool for managing complex projects. By breaking down a larger project into smaller, more manageable parts, project managers can improve project management, optimize resources, and provide clear communication and reporting on project progress. The subproject concept is an important part of the SAP PS module and should be considered for any project that requires complex management.